Modern project management demands efficiency and adaptability. Two frameworks – the Lean Project Delivery System (LPDS) and the ISO 21500 standard – offer powerful approaches, yet their full potential lies in understanding how they complement each other. This article clarifies the core principles of each system and highlights the synergy between them, providing insights for practitioners seeking optimized project outcomes.

The Lean Project Delivery System: Eliminating Waste in Action

The Lean Project Delivery System (LPDS) is a structured methodology rooted in Lean principles, designed to minimize waste and maximize value throughout the project lifecycle. Unlike traditional sequential approaches, LPDS emphasizes collaboration, continuous improvement, and a holistic view of the project, from initial definition to final delivery.

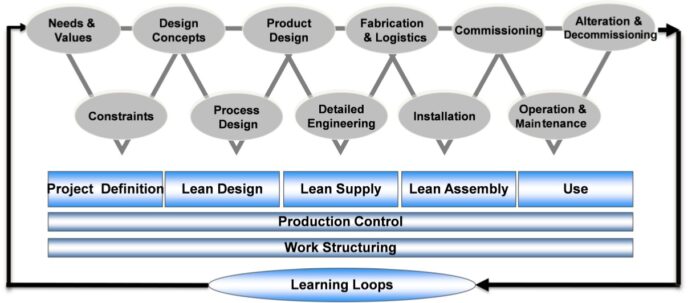

At its core, LPDS consists of 13 interconnected modules organized into four phases: project definition, design, supply, and assembly. These phases are supported by production control (often leveraging the Last Planner System and Target Value Delivery) and work structuring. A critical component is the post-occupancy evaluation loop, which ensures lessons learned from one project feed into the improvement of future endeavors.

The strength of LPDS lies in its ability to analyze the interplay between design and construction, identifying and eliminating inefficiencies at every stage. This requires a shift in organizational communication and authority protocols, as well as a willingness to embrace new contract models that incentivize collaboration and value delivery. As one key insight states, “To implement LPDS successfully, collaboration, early-involvement, aligned incentives, and integration of the project stakeholders is required.”

ISO 21500: A Flexible Guide to Project Management

ISO 21500:2012 is an international standard that provides guidance on project management, applicable across industries and project complexities. It’s designed to be adaptable, allowing organizations to tailor processes to their specific needs rather than imposing rigid, one-size-fits-all methodologies.

A key principle of ISO 21500 is its deliberate avoidance of prescriptive sequencing. Processes aren’t mandated in a fixed order; instead, they can be combined and arranged based on the project’s unique requirements. This flexibility is particularly valuable when processes interact and change, as it allows for dynamic adjustments to cost and design.

Furthermore, ISO 21500 intentionally excludes specific tools and techniques, leaving room for specialists to select the most appropriate methods for each project. This prevents the stagnation that can occur when organizations become overly reliant on outdated or ineffective tools. The standard also avoids defining strict inputs and outputs, further enhancing its adaptability.

The Convergence: Where Lean and ISO 21500 Align

The true power emerges when LPDS and ISO 21500 are viewed as complementary systems. Both emphasize flexibility, allowing processes to be adapted to changing conditions. LPDS provides a structured framework for eliminating waste, while ISO 21500 offers the broader guidance needed to manage projects effectively.

This synergy unlocks opportunities for innovation. The freedom to choose tools and techniques, combined with the adaptability of both systems, enables organizations to incorporate cutting-edge methods that would otherwise be constrained by rigid methodologies.

The ability to tailor processes, inputs, and outputs allows for a more holistic approach to project management. By embracing both Lean principles and the flexibility of ISO 21500, organizations can break down psychological barriers and foster a culture of continuous improvement.

In conclusion, the convergence of Lean Project Delivery and ISO 21500 provides a powerful framework for optimizing project outcomes. By embracing flexibility, collaboration, and continuous improvement, organizations can unlock new levels of efficiency and value delivery. Further research into this area is warranted to fully explore the potential of this synergistic approach