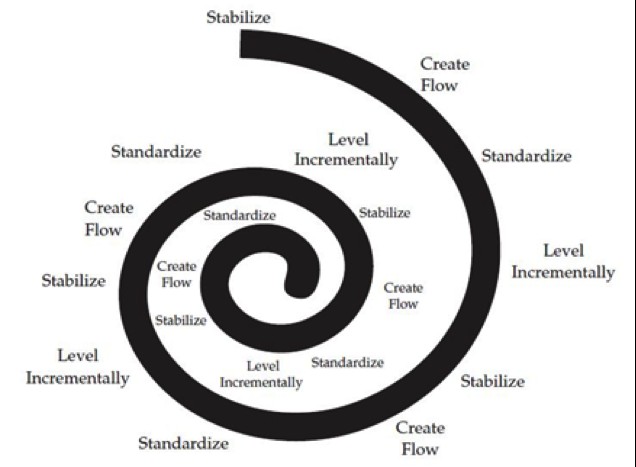

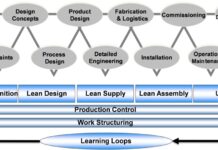

Takt time planning is a method for organizing work that aligns the pace of construction with the rate of customer demand, or in this case, project milestones. It’s a systematic approach to scheduling that focuses on balancing workflows across specific phases of work. Unlike traditional scheduling, which often prioritizes arbitrary deadlines, takt time planning emphasizes stability and flow to improve overall project performance.

Why is this important? Projects often suffer from chaos and unpredictability due to inconsistent work paces. Takt time planning aims to eliminate this by establishing a predictable rhythm that reveals bottlenecks and drives continuous improvement. This isn’t a new concept; it’s rooted in Lean Manufacturing principles, adapted for construction.

Зміст

The Core Idea: Stabilizing Workflows

The fundamental goal of takt time planning is to create a reliable plan developed with the entire team, not imposed from above. This means carefully considering what work should be paced, at what speed, and in what increments. The process is iterative and best implemented early in a project, as design decisions directly influence the means and methods of construction.

The benefit? When activities move at consistent paces, projects become more manageable. This predictability allows teams to identify and address inefficiencies, leading to shorter durations and fewer surprises.

How Takt Time Drives Improvement

Takt time planning isn’t just about speed; it’s about flow. By releasing work in smaller batches, teams can reduce dependencies and accelerate progress. This approach forces better coordination between trades and exposes areas where handoffs need streamlining.

Consider this: A project with consistent, smaller work releases will likely finish faster than one with large, disruptive batches. The key is understanding how much work is on the floor, its location, and how each trade prefers to operate.

Example: Overhead MEP Installation

Imagine an overhead MEP installation phase for plumbing, ductwork, and electrical conduit. Using takt time planning, the work can be paced at a 5-day cycle, moving through quadrants on two floors. In this example, plumbing goes first, followed by ductwork, then electrical conduit.

The result? By breaking the work into smaller segments, the project can finish weeks earlier than if the entire floor had to be completed before moving on. This demonstrates the power of small batches and controlled pacing.

The Bigger Picture

Takt time planning is a dense topic with a rich history. Future posts will explore the evolution of this method, its integration with location-based scheduling, and its connection to other Lean Construction concepts.

In conclusion: Takt time planning is a powerful tool for structuring work, improving predictability, and driving continuous improvement in construction projects. By prioritizing flow, small batches, and team collaboration, it offers a path toward more reliable and efficient project delivery